Robot End Effector

Team Project • FEA • 3D Printing

Summary

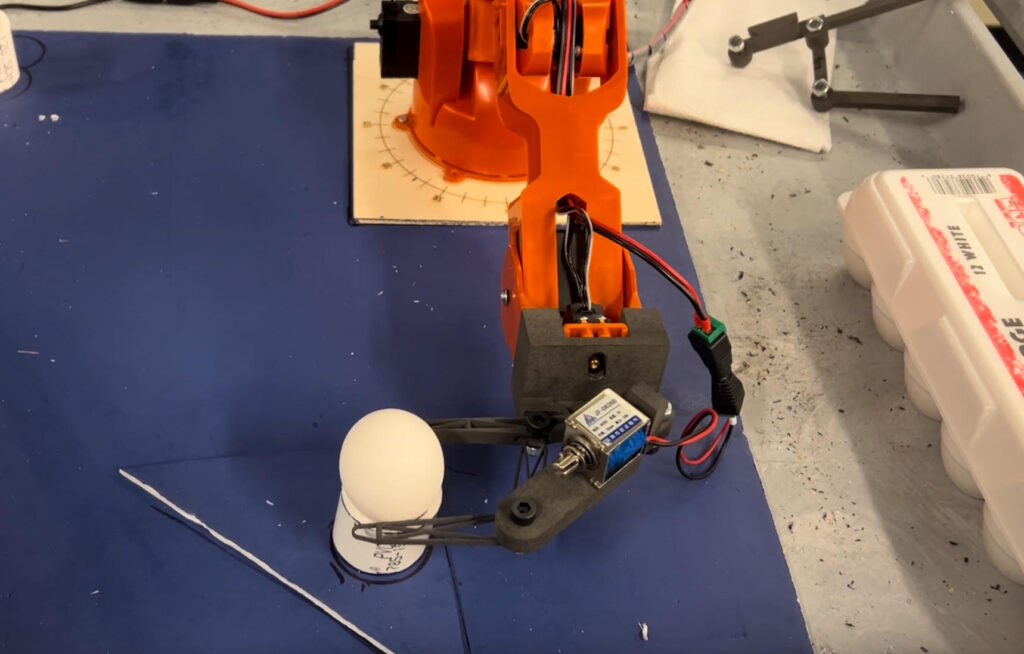

The purpose of this project was to design a robot end effector that would be able to attach to the TINKERKIT BRACCIO robot and allow the robot to successfully pick up an egg and move it around without damaging the egg itself. Constraints such for the deflection (1mm & 2mm) were provided, as well as the corresponding load limits discussed later. The goal was to also try make the assembly lightweight as possible, with part of the project being graded on the weight of the part.

My Role

- Design and test the static component of the end effector

- Use FEA to test the initial design & revise the design based on the results of the test

- Coordinate and work with partner to ensure functionality of the combined static and dynamic end effectors to fulfill end goal

Design Constraints

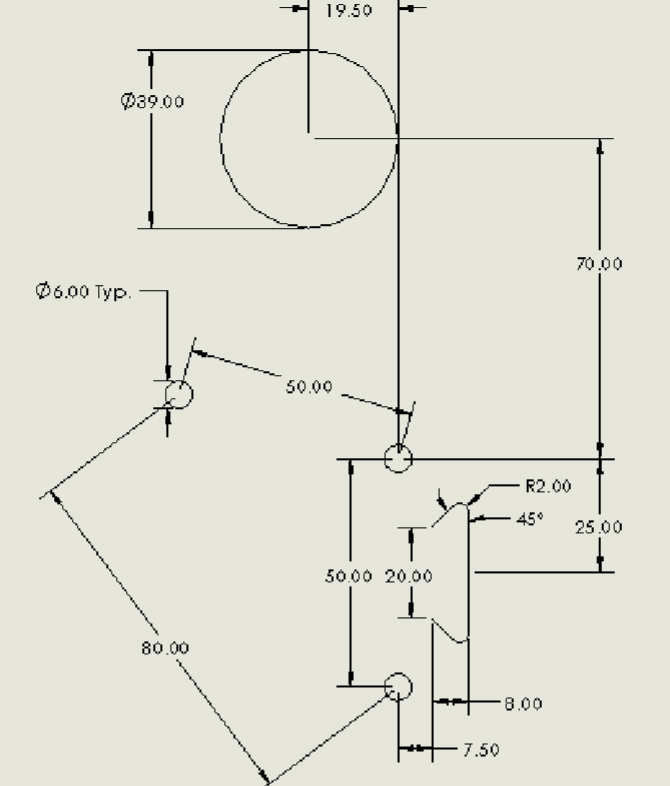

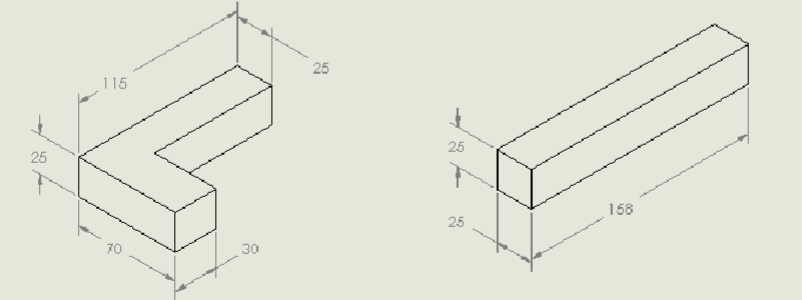

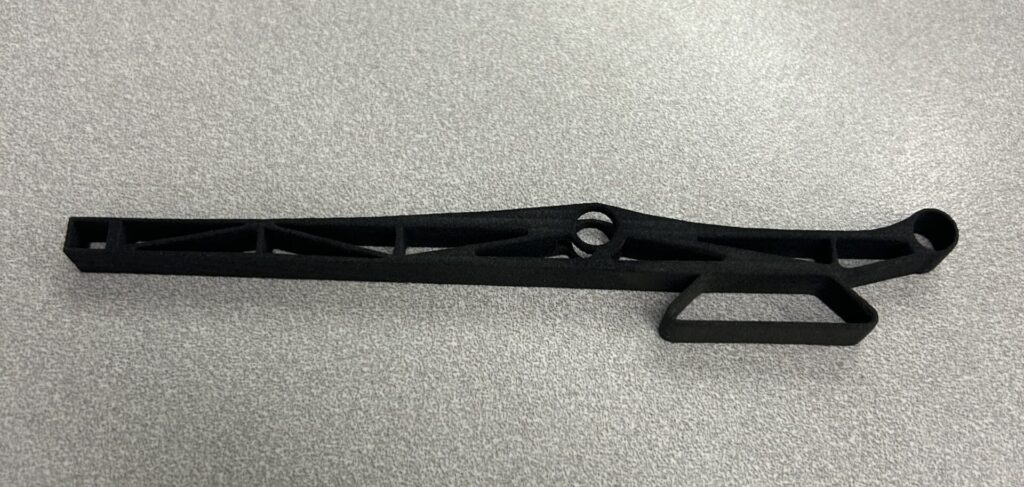

A variety of design constraints were provided including geometric as well as load limits were provided, shown below. These geometric constraints were put in place to ensure correct fitment with the solenoid assembly powering the movement of the effector as well as the dovetail that allows the assembly to mate with the robot arm. Likewise the material that our part would be constructed out of was also predefined. Nylon 12 (Formlabs) was selected, with properties E = 1850 MPa, Ys = 50MPa & G = 660 MPa.

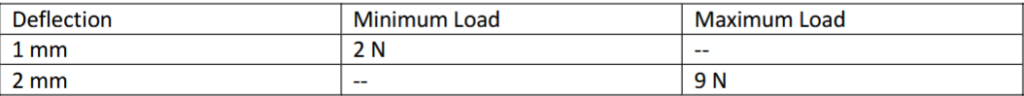

Load Limit Constraints

Design Process

Prior to jumping to CAD, we performed some intial calculations working under the geometric constraints, which would be the largest and strongest physically possible design. Of course, the calculated factor of safety was orders of magnitude higher than standard practice, which told us we had significant material to remove in order to save significant weight. With this in mind, we started work design, eventually landing on 2 iterations that fulfilled theoretical requirements

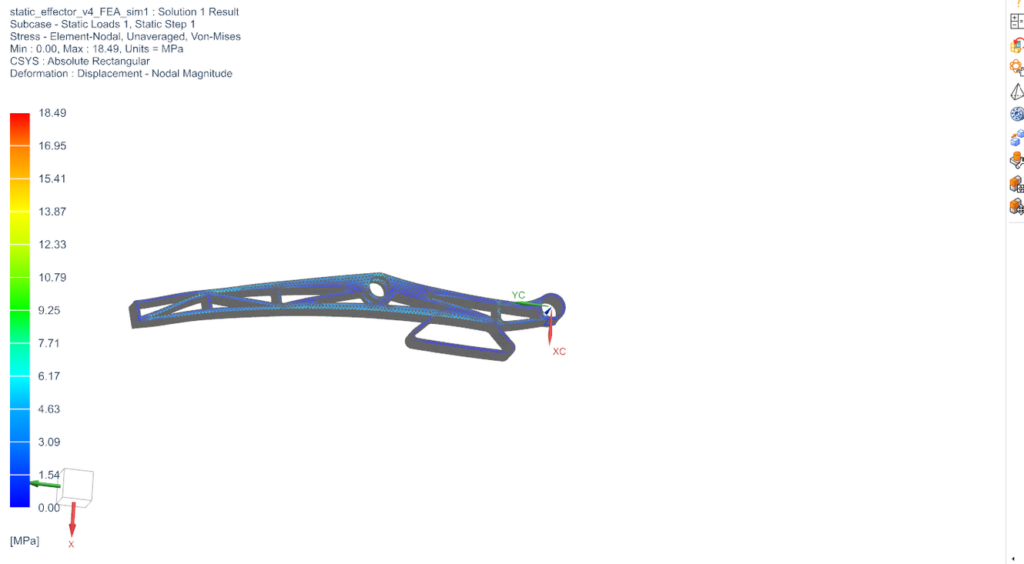

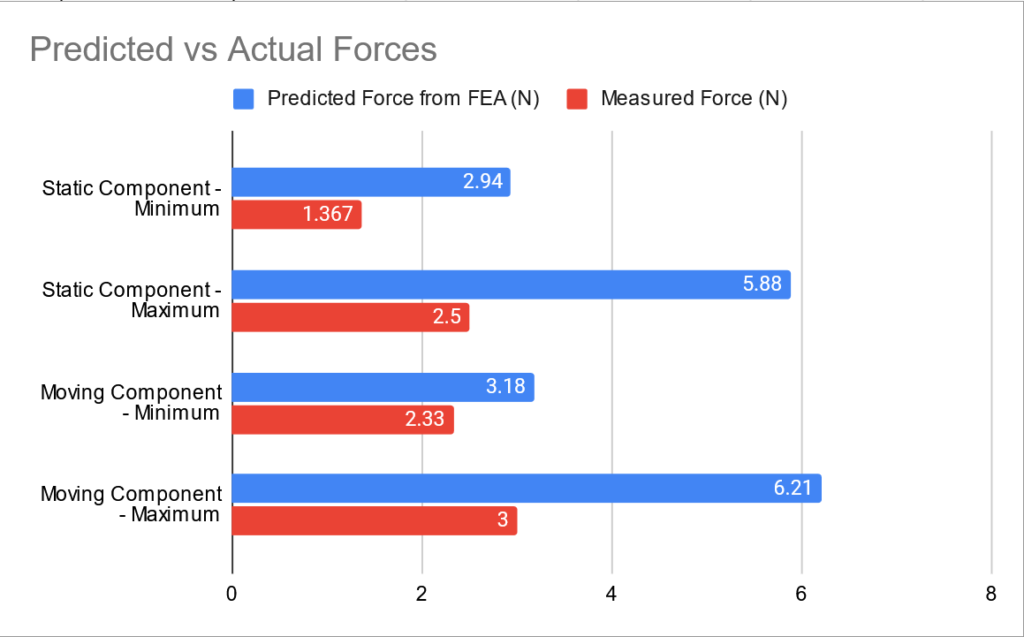

The final design able to fit the solenoid assembly, with all bolts as well as the dovetail fitting well and snug. In addition, the data from our FEA analysis produced the following :

1mm Reaction Force in x: 2.940 N

2mm Reaction force in x: 5.880N

Nodal Stress @ Max deflection < yield strength of material.

Our design likewise was one of the lightest in the class, thanks to the complex truss design that saved weight in areas that were under minimal stress, such as the completely hollowed out dovetail. The final design weighed in at only 117g, including all fasteners and solenoid components.

Testing & Results

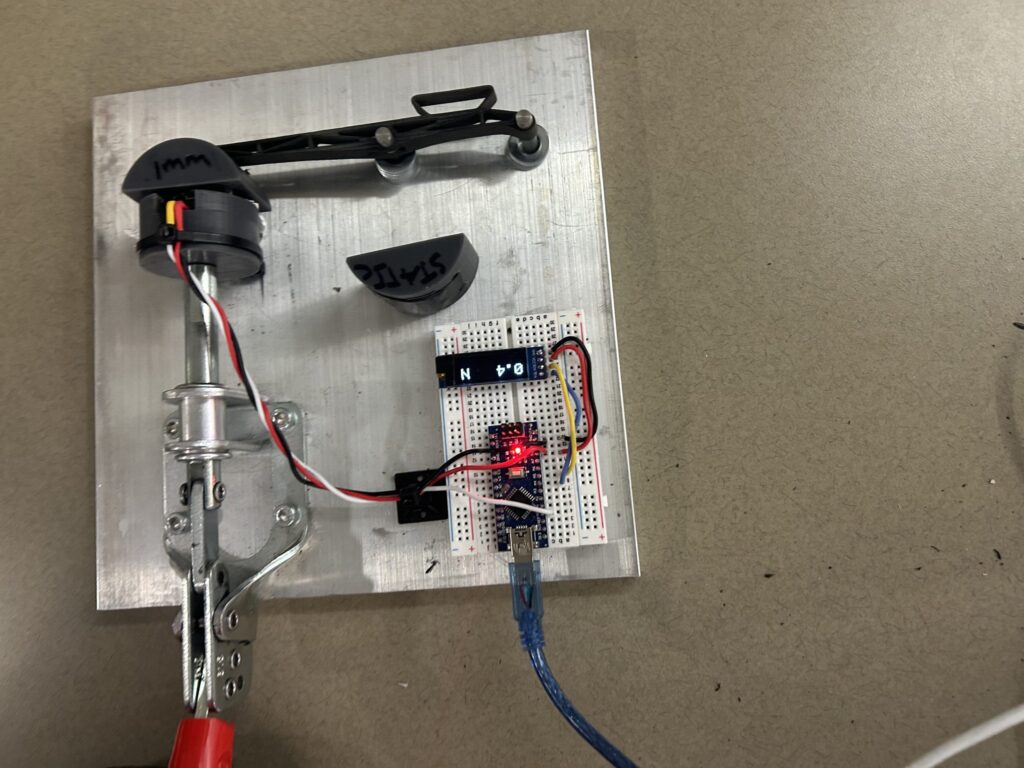

The final step was to test the end effector parts in both a live setting and a controlled setting, with the device being tested both directly on an egg and on the jigs shown below, which measure the forces produced at given deflection (1mm & 2mm). This would also provide us with data to compare our results the simulated data from our FEA.

Both live testing & the measurement jigs showed that there was improvement to be made for our part with regards to the force as well as the functionality of the part. In live testing, the effector was able to successfully grasp and pickup the egg. However, due to the low contact area of the end effectors with the round surface of the egg, the egg eventually slipped out of the effector when the arm moved too fast. As shown in the results on the right, the static efector did not produce sufficient force at 1mm of deflection, in contrast to the FEA results, which shows how there can be discrepancies between the real measured forces and what the FEA produces. One potential explanation for the variation in between the testing data and the FEA was how the behaviour of nylon-12 changes with wall thickness and printing direction, variables that we had not put much consideration into.

In spite of the final testing results, the project was a successful learning experience, being my second in depth attempt at using FEA. While the forces and final testing showed further improvements to be made in the design, the lightweight design showed that it was a viable option for the use case, as well as providing us with great practice in mechanical design.